Who are Connected Workers?

Connected workers are front line workers who execute their jobs with the help of digital technologies and the devices they naturally use in the flow of work (including phones, laptops, tablets and Smartglasses).

They are empowered with real-time information about equipment, processes, work instructions, and more.

A Front Line Worker Platform specifically focuses on optimizing the human element in your machine monitoring and service tasks. These platforms do this by providing improving training, standardizing best practices for work execution and providing remote assistance when the unforeseen occurs.

Trends that are making Connected Workers an inevitability in the future

- Developments in 5G Internet have made adopting cloud-based technologies easier for large enterprises as well as smaller companies.

- Senior workers must be replaced with less experienced employees. This has created a fear for manufacturers of losing crucial tribal knowledge.

- The manufacturing process is becoming more complicated and it is difficult to provide effective training to employees with paper based processes.

- New employees are digital natives and demand connectivity from their employers.

- IoT, AR, machine learning, AI, smart devices, and other technologies are becoming mainstream.

- Compliance has become a competitive asset andConnected Worker platforms offer improved compliance verification.

- A demand for sustainability requires greater operational efficiency to reduce environmental waste.

Benefits of a Connected Worker platform

Workers become more efficient and effective when they are connected to their environments and given true visibility. They can make better, data driven decisions and can unlock several benefits such as:

- Reduction in human error

- Increased productivity

- Improved worker safety

- Saving valuable time and money

- Continuous asset monitoring

- Increase in Overall Equipment Effectiveness (OEE)

- Resolve issues and machine downtimes quickly.

Connected Worker technologies

- Platforms: This includes any software or hardware leveraging artificial intelligence and real-time data to help front line teams improve overall productivity.

- Interfaces: Modern technologies such as AR-enabled headsets enable peer-to-peer information sharing and resolving machine downtime remotely.

- Smart sensors and IoT devices: Sensors attached to machines and equipment provide a holistic view of its condition and processes in real-time.

- Cloud and edge computing: Workers can communicate with each other or access resources from anywhere using the cloud.

- Improved microlearning: Train new employees rapidly with the help of visual work instructions and microlearning resources provided on-demand.

- Digitized work instructions: Adopting digital work instructions in place of paper-based assignments to accelerate productivity and reduce time wastage.

We can help you

VReadyNow is a high-technology company focused on providing business to business application, products, and services, with expertise in spatial computing, immersive and interactive platforms based on XR technologies. Founded in 2016 by former Fortune 500 Companies Executives. VReadyNow has its HQ in Miami, USA, and offices in Mexico City, Mexico and Buenos Aires, Argentina.

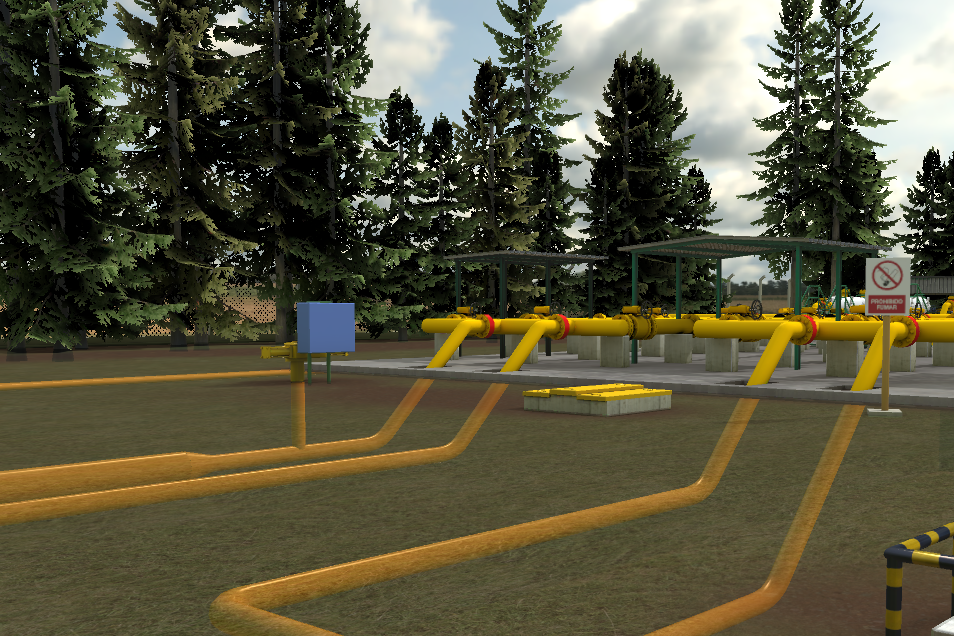

VReadyNow created SmartWorkAR; asoftware platform to manage procedures and instructions easily and remotely with AR tools. SmartWorkARit’s a cloud based platform that allows field technicians perform guided procedures, with Augmented Reality visual instructions assistance. It mitigates trained workforce scarcity and highly improves field workforce productivity. SmartWorkARis available for smart glasses, smart phones and tablets.

SmartWorkAR® is based on cloud services and is available for Smart Glasses and Industrial Tablets under Android®.

For more information, please visit http://smartworkar.vreadynow.com/